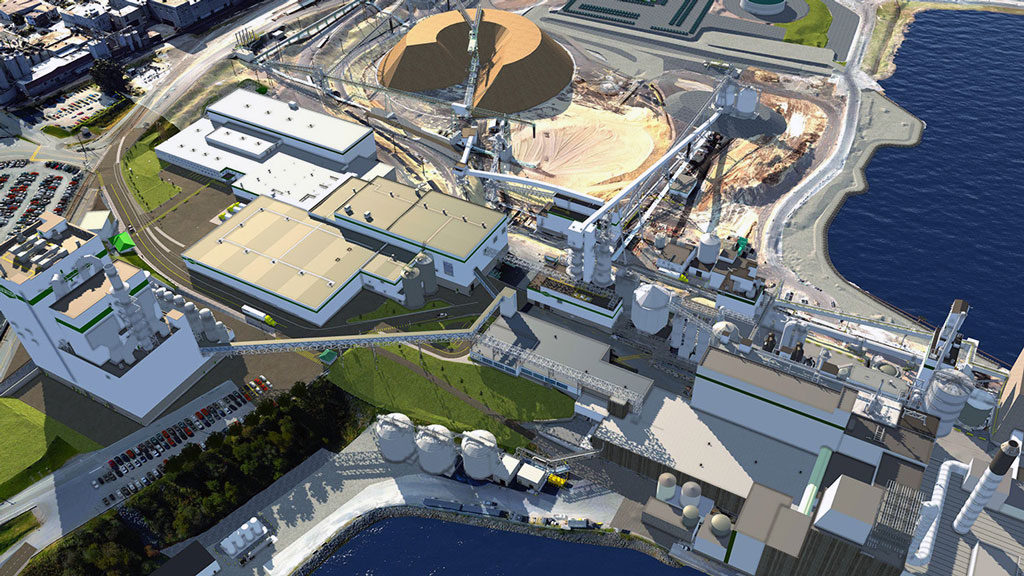

Preliminary design work has begun on the construction of a new recovery boiler at an Irving Pulp & Paper Ltd. mill in western Saint John, New Brunswick. The boiler will increase the plant’s green energy capacity, dry more pulp and nearly double production capacity.

The $1.1 billion project, called NextGen, is the largest investment in Canadian forestry since 1993 and one of the largest industrial construction projects in New Brunswick’s history.

This will make the site one of the most productive kraft pulp mills in the world.

The company has submitted an environmental impact report (EIA) on the project to the New Brunswick Ministry of Environment and Local Government, which is overseeing the process.

Construction is expected to begin in spring 2025 following completion of the EIA procedure.

The project involves replacing and decommissioning a 1970s-era recovery boiler at the historic plant that runs on Bunker C heavy fuel oil and is nearing the end of its life. This will enable the plant to increase production by 66 percent and implement several new environmental improvements, including a new turbine and green energy generator. Construction is expected to take four to six years.

“These upgrades will ensure that the Saint John pulp mill remains at the heart of the province’s forest products supply chain, providing a regional market for wood chips, bark and pulpwood,” said Mark Mosher, vice president of Irving Pulp & Paper, in a prepared statement.

Arlene Dunn, executive director of the Saint John Construction Association, said in a social media statement that the project will play a critical role in securing the forestry sector for the next 50 years and will help decarbonize the electricity grid by generating 120 megawatts of renewable energy.

“Projects like this not only strengthen the craft sector but also provide employment opportunities for local workers and contractors. They ensure knowledge transfer and skills development and ultimately contribute to the growth and sustainability of the region and the province.”

The new recovery boiler will be 20 stories tall and housed in a 250-foot-tall building being constructed on what is currently a parking lot on the west side. It will allow the plant to increase its output and generate enough energy to operate without purchasing outside power.

The building itself will be a steel frame structure on a concrete slab and will have steel cladding.

Other important environmental improvements include the construction of a steam turbine to generate green electricity and technical improvements to reduce water consumption. The decommissioning of the oil-fired boiler will reduce the amount of CO2 emissions from the plant.

The new recovery boiler and steam turbine, along with the construction of a new lime kiln, will allow the mill to increase air-dried pulp production from 1,000 to 1,800 tons per day, while increasing energy output from 30 to 140 MW. The excess electricity will be sold to New Brunswick Power, according to the EIA.

During the four-year construction phase, approximately $539 million will be spent directly and indirectly on labor.

At the same time, the project will generate over $172 million in tax revenues for provincial and municipal governments, $539 million in labor income, increase the province’s GDP by $711 million, result in $409 million in fiscal spending, open new opportunities for hundreds of local contractors, and create over 2,200 person-years of jobs for skilled workers such as steelworkers, millworkers, carpenters, masons and laborers.

In the long term, the plant will contribute $10 million annually to provincial and municipal tax revenues, create 600 additional jobs in the forest supply chain and through induced effects, and increase labor incomes in the forest products supply chain by 38 percent.

According to the EIA, the new recovery boiler will be the most efficient in North America, if not the world. Air emissions of nitrogen, sulfur dioxide and particulate matter will be significantly reduced. Clean-burning natural gas will be used as auxiliary fuel in the recovery boiler and in a recausticization plant, reducing greenhouse gas emissions by eliminating the need for heavy fuel oil.

The new boiler will produce more than twice the amount of steam as the existing model. The steam will be distributed to the turbines and drive the generators, making the mill energy self-sufficient.

Currently, the plant’s recovery boiler stack emits a water vapor plume, but the new boiler’s flue gas stack will use dry technology to clean air emissions and reduce the plume.

The increase in production at the mill will require more softwood wood chips, but it is not expected to increase the area of forest logged in New Brunswick as the chips will be obtained from other sources. Improved forest use by all stakeholders, including private forest owners, will include the use of the canopy of rotten, crooked or forked trees left in the forest to rot, as well as the harvesting of mature stands planted by the Company nearly 50 years ago.

The plant has undergone several upgrades over the years. The facility employs nearly 500 people and is the largest industrial employer in New Brunswick.