The TATAs! Who doesn’t know them? Well, this time their plan is bigger and bolder. They are moving into the nuclear field. Tata Steel, one of the largest steel producers in the world, is exploring nuclear energy to produce green steel.

Small reactors, big ambitions: Tata reinvents green steel

Currently, the steel giant is looking at many factors that could play a crucial role in the production of green steel. The aim is to set up around 200 BSRs in the nuclear power sector. One unit will have a capacity of 220 MW, which together would provide about 45 GW of power.

Although Tata Steel has not made an official comment, sources suggest that the company is interested in transitioning to producing green steel. This move comes despite Tata Steel not exporting significant volumes to Europe, where the Carbon Border Adjustment Mechanism (CBAM) is set to come into effect on January 1, 2026. The CBAM will impose a tariff on certain imported goods, including steel, based on their greenhouse gas (GHG) emissions during production. This measure is designed to prevent European producers from being undercut by imports with a higher carbon footprint.

According to media reports, other steel companies are also considering BSRs, but Tata Steel seems particularly interested. If the plan goes ahead, Tata Steel intends to use the electricity generated by these BSRs to power electrolyzers to produce green hydrogen. This hydrogen would then replace coking coal used in steelmaking, significantly reducing carbon emissions. In doing so, Tata has laid out a clear path to decarbonizing one of the most difficult sectors.

The strange case of the BSRs…

Bharat Small Reactors (BSRs) are nothing but SMRs that the US, Canada and Russia have had great success with. They can address many of the design and innovation challenges that India’s power sector is currently facing.

BSRs can be installed in remote areas, expanding energy access to these regions and providing reliable energy to isolated locations. In addition, BSRs are characterized by shorter construction times. Their modular design makes them easier to build compared to conventional reactors.

Another important feature is that they are cost-effective due to their smaller size and modular design. They reduce costs across their entire life cycle – from construction to decommissioning – and make nuclear energy more affordable and sustainable for India.

In conclusion, Bharat Small Reactors will transform India’s energy landscape by providing a versatile, cost-effective and timely solution to the country’s growing energy needs.

Source: insightsonindia, BSR

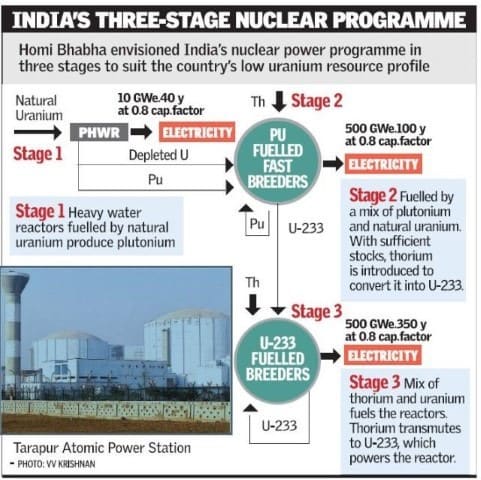

Indian Finance Minister Nirmala Sitharaman outlined the government’s plans to build BSRs in collaboration with the private sector. She praised India as a pioneer in this field and pointed out that the Nuclear Power Corporation of India (NPCIL) has been operating 15 pressurized heavy water reactors (PHWRs), each with a capacity of 220 MW, for years.

Recently, Atomic Energy Commission member RB Grover informed the media that these 220 MW PHWRs are being upgraded. The modified versions, known as BSRs, are to be licensed to the private sector.

Union Minister Dr. Jitendra Singh also announced that India’s nuclear energy capacity is expected to increase by around 70% in the next five years. Currently, the installed capacity is 7.48 GWe and is expected to increase to 13.08 GWe by 2029.

Tata Steel is pioneering sustainability in the Netherlands

Green steel is steel produced without carbon emissions. By 2030, Tata aims to reduce its carbon emissions by 40% and become 100% carbon neutral by 2045. Their production process focuses on minimizing environmental impact and promoting the circular economy. They believe that increasing steel recycling and increasing scrap utilization from 17% to 30% by 2030 will significantly improve sustainability.

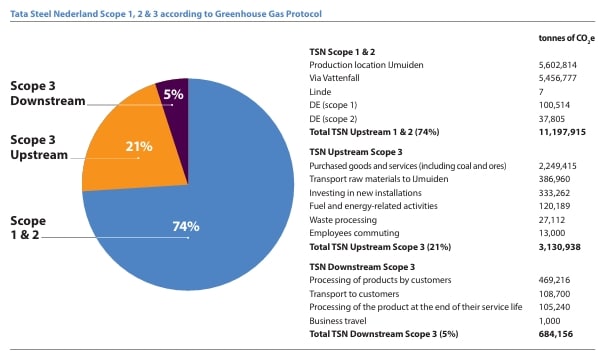

Tata Steel’s plant in Ijmuiden, the Netherlands, has become one of the most carbon-efficient steel plants in the world, ranking in the top three in the Worldsteel Association benchmark. The plant’s emissions per tonne of steel are 7% below the European average. Despite this achievement, Tata Steel is still responsible for 8% of all CO2 emissions in the Netherlands. The company is committed to reducing this percentage by all possible means to support the country’s climate goals.

Source: Tata Steel Sustainability Report

To use nuclear power to produce green steel, Tata Steel will first need to make changes to the Atomic Energy Act. These changes are required to allow private ownership and operation of nuclear power plants in India. The government is reportedly considering these changes to the law to kickstart the project. We will keep you updated on further developments in this exciting area.

)